![]() Made in USA • Patented Technology

Made in USA • Patented Technology

PrecisionVac™

Turbocharges

Rapid-Chill &

Rapid-Flavor Infusion/

Food Treatment

Experience the future of food preparation with our Multi-Capability system that offers Rapid-Chill and Rapid-Flavor Infusion/Food Treatment in one unit. ![]() Made in USA • Patented Technology

Made in USA • Patented Technology

PrecisionVac™ Turbocharges Rapid-Chill and Rapid-Flavor Infusion/Food Treatment

Experience the future of food preparation with our Multi-Capability system that offers Rapid-Chill and Rapid-Flavor Infusion/Food Treatment in one unit.What the industry is saying about our technology

“PresicionVac is a game-changer for the culinary industry. This is a revolutionary improvement in kitchen efficiency, sustainability, and food quality, all while reducing energy costs”

Rich Rosendale, CMC, Founder or Rosendale Collective

"Implementing PrecisionVac will dramatically cut cooling times, improve food safety(under HACCP requirements), and improve food quality, with the added benefit of at-scale food treatment"

Chef Colin Smith, Executive Chef, Roundabout

“The PresicionVac technology has transformed our food production processes, allowing us to deliver fresher products to our customers while reducing our carbon footprint.”

Jordan Lichman, Director, West Coast Operations, Thistle

Hear what the industry says about the EVC

Industry leaders trust our technology to transform their operations

Revolutionary Multi-Capability Technology

Our innovative solutions combine rapid-chill and rapid-flavor infusion/food treatment in one efficient system, proudly manufactured in the USA. By leveraging our patented PresicionVac™ technology, we provide revolutionary food processing capabilities that preserve and enhance flavor and texture while dramatically reducing processing time.Schedule a consultation with our specialists

Explore Our IP Portfolio

Rapid-Chill

Our industry-leading technology rapidly chills food up to 5x faster than conventional methods, while preserving quality and reducing energy consumption. Made in USA with premium components.

Learn more

Rapid-Flavor Infusion/Food Treatment

Transform your menu offerings and your bottom line with our patented rapid-flavor infusion/food treatment technology that processes food up to 25x faster than traditional methods.Learn more

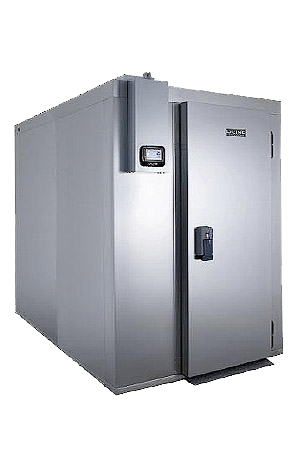

Our Products

Experience our revolutionary dual-capability systems that combine rapid cooling and food treatment in one efficient unit.

Proudly manufactured in the USA with premium components.

Get in Touch With Us

Have questions about our rapid chilling technology? Our team is here to help you find the perfect solution for your needs.Contact Information

info@culinarysciences.com

Phone

+1 408-590-7067

Headquarters

P.O. Box 110095

Campbell, CA 95011

United States

Production Facility

Suite 7

565 East 34th Avenue

Apache Junction, AZ 85119

United States

Office Hours

Monday-Friday 9am - 6pm (Pacific Time)