FOOD-TREATMENT

![]()

CSI EVC Product Application Note

Lightning-Fast Flavor Infusion

- Game-changing Flavor Enhancements: CSI’s Extreme Vacuum Treatment (EVC) technologies enable chefs and food manufacturers to differentiate their product offerings, with highly craveable proteins, vegetables, and fruits

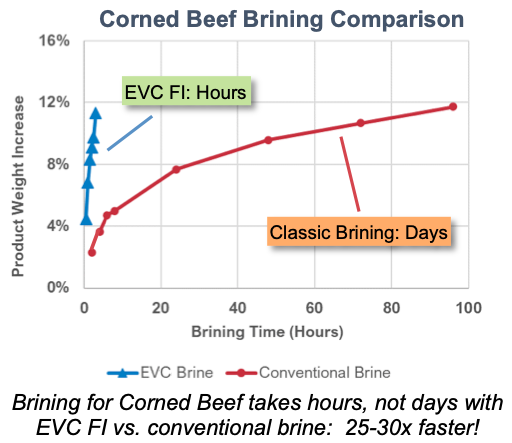

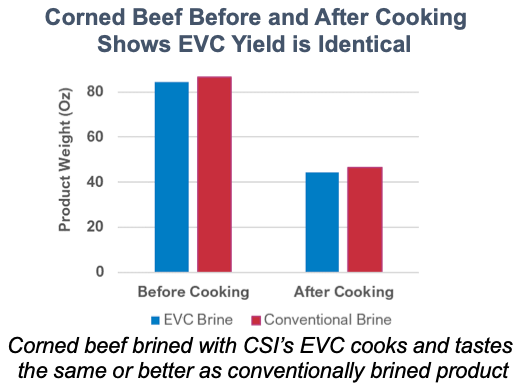

- Huge Time Savings: CSI’s EVC products accelerate Flavor Infusion (FI) into foods at a fraction of the time of conventional Marinating and Brining (M&B)

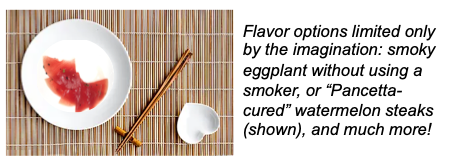

- Supports Plant-Forward Dining Choices: Expected WW CAGR through 2027 is at least 11% for plant- based foods. EVCs’ FI is a new technique to enable chefs to create culinary innovations, and benefit from this highly dynamic market.

Background

- Brines typically use a salt solution, whereas Marinades contain acids (e.g., vinegar), oils, enzymes, etc.

- Brining (wet or dry) works by osmosis, moving the salt solution into the food, increasing its juiciness and flavor

- Marinades flavor and can tenderize some types of foods, such as tougher cuts of meat

Volume food prep operations often avoid traditional M&B due to extended refrigeration time and food safety complications

EVC Flavor Infusion Advantages

- CSI’s EVC technology requires hours, not days, to infuse flavors from the brine or marinade into the product, by dramatically accelerating the osmotic transfer process

- The EVC FI approach offers a new capability for Efficient Flavor Infusion, proven for both proteins and plant-based foods

- In many cases, the EVC FI process infuses flavorings deeper within food items vs. conventional M&B (e.g., static and vacuum tumbling) methods

- CSI’s EVC FI technology supports recipe innovations in the high-growth Global Plant-Forward arena. Many leading companies and universities see this capability as a game-changer, to enable the creation of delicious, healthy, and profitable menu choices.

The Technology

- CSI’s EVC products utilize ultra-low pressure technology, not only to cool foods but also for Flavor Infusion, both at lightning speed

- Evaporative phenomenon accelerates flavor penetration into food products