RAPID-CHILL

CSI EVC-300™

Revolutionizing Rapid Food Chilling

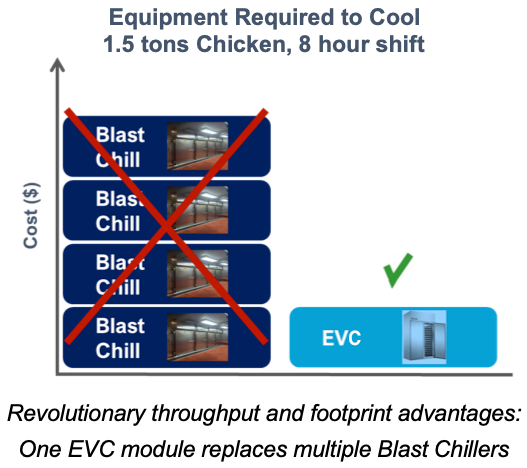

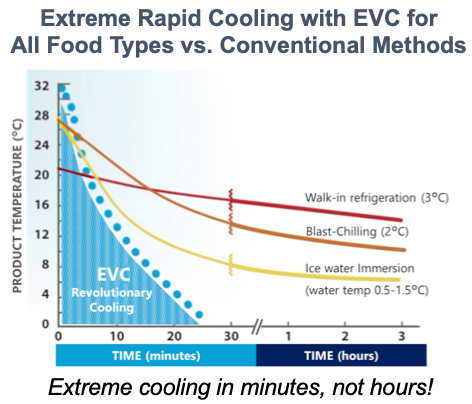

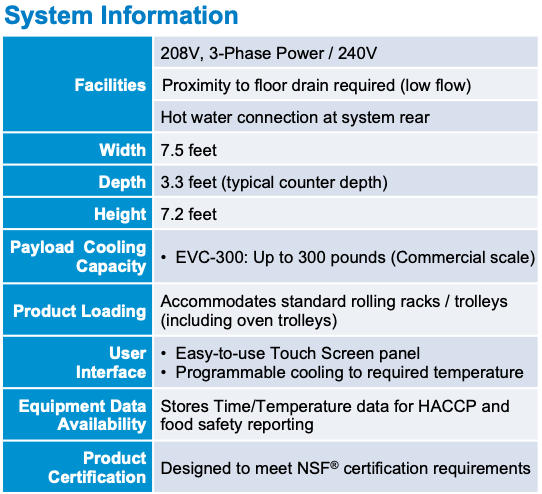

- Major Throughput & Cost Advantage: CSI’s Extreme Vacuum Cooling™ (EVC) cools foods up to 500% faster than Blast Chillers, uses less energy, and requires less equipment

- Enhances Food Quality: EVc cools food uniformly across the batch – for longer shelf life, reduced waste

- Rapid-Chill™ All Food Types: From oven to 40°F in under 30 minutes, often less. Dense, prepared foods to leafy greens; proteins, vegetables, sauces, …everything!

CSI’s EVC Products offer 5 key value propositions

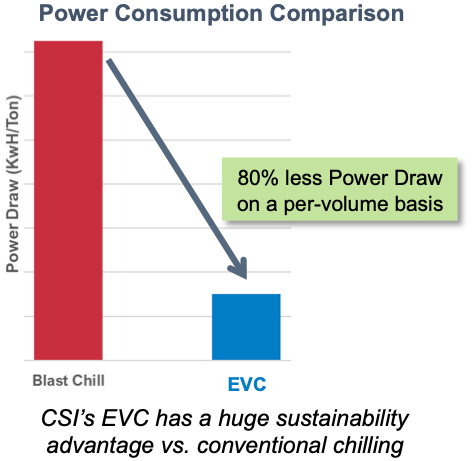

- Sustainability: Energy usage is 80% lower, with a smaller footprint, than Blast Chillers

- Higher Throughput: Huge reduction in cooling time versus Refrigeration and Blast Chill methods; less equipment is required, saving floor space

- Higher Food Quality Across Batch: Cools food uniformly, independent of its location in the module; ensures consistent product with no “edge freeze”

- Extended Food Shelf Life: Faster chill time delivers food that lasts longer, with less waste

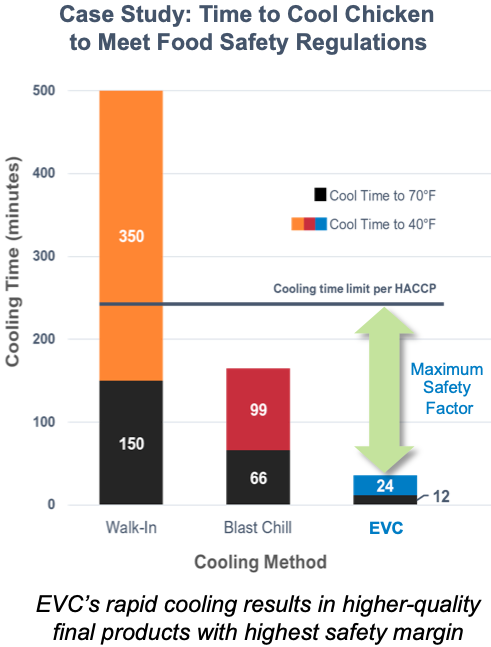

- Food Safety Assurance: Rapid cooling ensures food stays out of the Danger Zone, per HACCP regulations

The Technology

- Extreme Vacuum Cooling (EVC) utilizes ultra-low pressure for evaporative cooling

- NOT a refrigeration unit; only the food is cooled, not the environment around it

- EVC equipment consumes no energy when idle or between runs, unlike Blast Chillers

CSI has vast experience with ultra-low pressure vacuum systems. Our patent-pending, innovative technology enables a disruptive, new performance standard in Food Service.

Culinary Features & Benefits

Cool Benefits

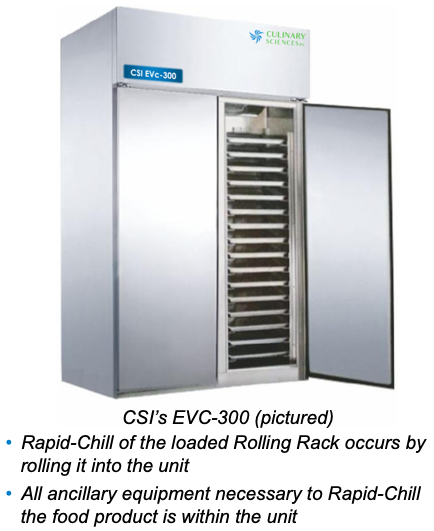

- CSI’s EVC-300 Rapid-Chill modules cool prepared foods extremely rapidly, from oven to refrigerator temperatures, in just minutes, not hours, saving time, energy, and valuable floor space

- Example: Chicken breasts (or whole birds, etc.), out of the oven at 165°F, reach 40°F in as little as

20 – 30 minutes, and are cooled uniformly - Unlike blast-chillers (which often freeze outer surfaces of foods and leave the centers warm), Extreme Vacuum Cooling uniformly cools through the food with no freezing

- Regardless of the required final temperature, EVC products deliver sustainable and extremely rapid cooling, that maintain food quality, consistency, and flavor across the batch

CSI Services

- Demonstrations

- Installation, setup, and chef training

- Application and Technical Support

- Site Maintenance

- Standard Warranty

- Extended support service available

The Transformative Rapid-Chill Solution

for Controlled Environment Agriculture (CEA)

- Sustainable, rapid cooling for Next-Gen sustainable farming:

EVC offers huge energy and time savings for CEA commodities compared with conventional refrigeration cooling - Ultra-clean, high-tech operating environment:

EVC’s food-grade cooling systems and manufacturing techniques maintain product cleanliness and quality - EVC’s Rapid-Chill technology supports recent FDA safety recommendations for effective rapid cooling of produce grown using CEA

EVC’s key value propositions extend to CEA products

- Sustainability: EVC uses 80% less energy than Refrigeration methods, with a smaller footprint

- Higher Throughput: Huge reduction in post-harvest cooling time for CEA versus Refrigeration; and, less space is required

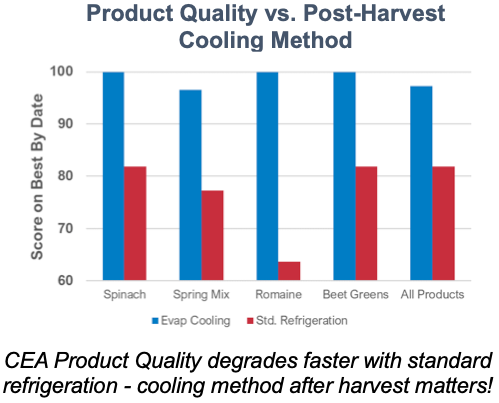

- Higher Food Quality Across Batch: Precision, uniform cooling with patent-protected technology ensures consistent CEA products with no “edge freeze”

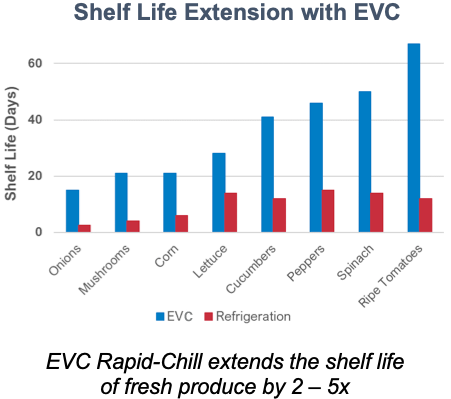

- Extended Food Shelf Life: CSI’s Rapid-Chill™ technology reduces waste, increasing CEA yields

- Food Safety Assurance: Rapid cooling ensures food reaches refrigeration temps ASAP to minimize risk

EVC’s Cool Benefits for CEA

- CSI’s EVC equipment solutions are scalable; with the broad range of CEA facilities and products, one size does not fit all

- Time- and temp-based process control ensures highly uniform cooling and no edge freeze

- Minimal dehydration, minimal yield loss

- EVC’s technology has demonstrated 2 to 5 times increase in shelf life, vs. refrigeration

- 15 – 35% improvement in product quality vs. conventional refrigeration techniques

CSI’s EVC for CEA

- After harvest, CEA products are rolled into the EVC for precision Rapid-Chill

- Product cooled (harvest temp to 41 F) typically under 6 minutes