SUSTAINABILITY/ESG

![]()

ESG trends in the industry are tailwinds for our demand

U.S. Ratification

of the Kigali Amendment

Commitment to phase out Hydrofluorocarbons (HFCs), a group of chemicals used in traditional refrigeration, by 2045

Reduced Food Waste

in Catering Services

1 food kilo of food waste is equivalent to three kilos of CO2 emitted

Agriculture Industry

Commitment to Sustainability

Large agriculture players committed to zero emission and reduced energy consumption

Hospitality Industry

Commitment to Reducing CO2

Large players have aligned themselves with SBTi, committing to reducing carbon intensity

GHG Analysis

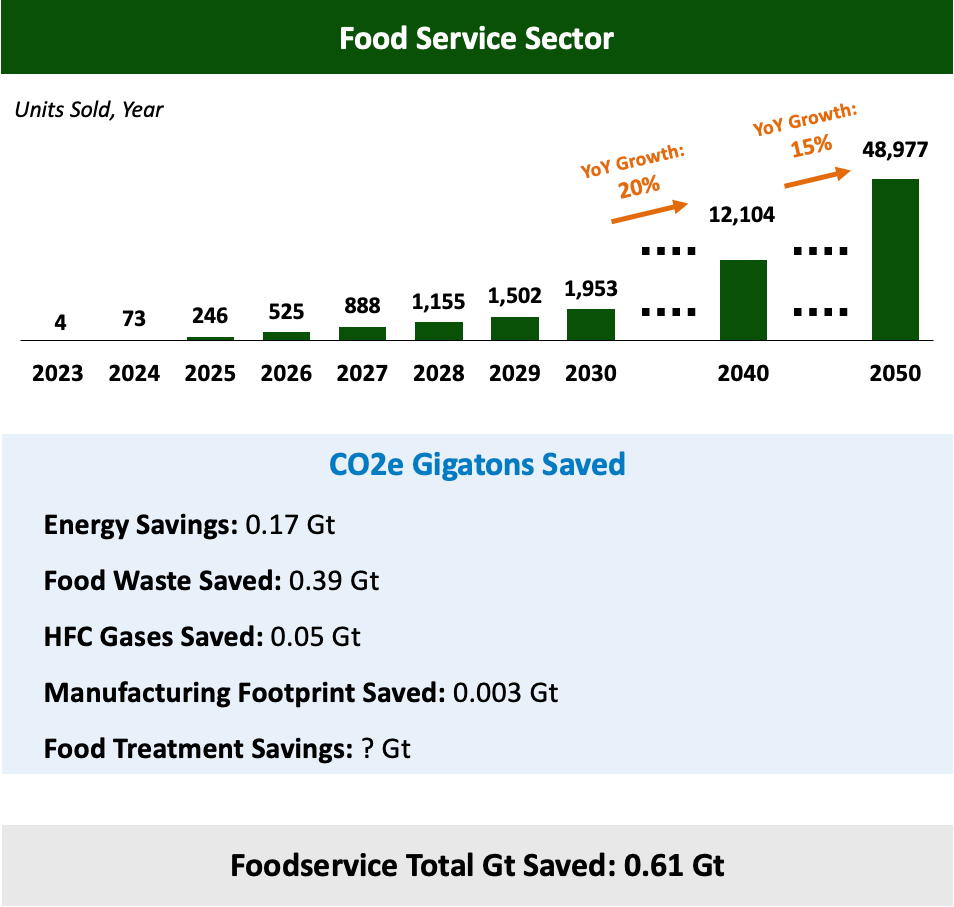

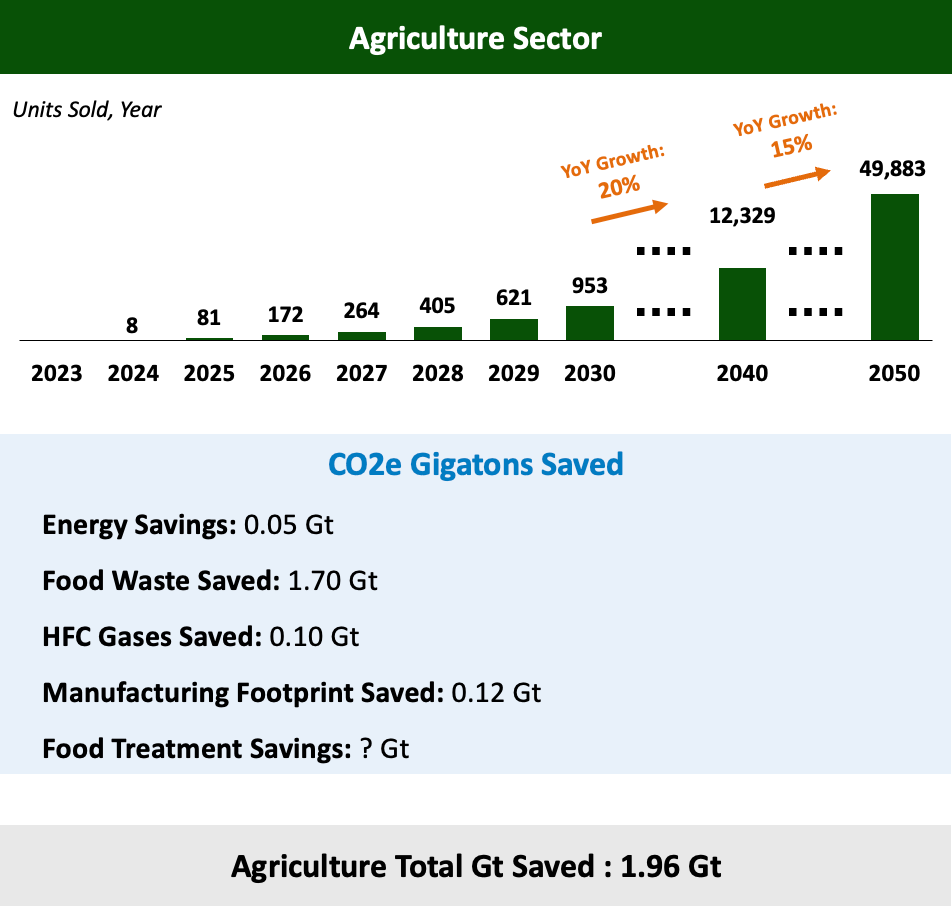

CSI’s CO2e Emissions Analysis until 2050 – Quantified Variables

Variable 1: Energy Savings

Food service: Assumed a fixed capacity of food cooled per day, quantified the KwH differences of using an EVC-300/+ vs a blast chiller

Agriculture: Assumed the KwH costs of a standard-size agriculture chiller warehouse, and applied an energy efficiency ratio for using EVC-300+ machines instead.

Variable 2: HFCs Gases (Freon Gases)

NOTE: Current refrigeration methods used in Ag and Food Service make heavy use of refrigerants, and have annual re-charge budgets to be factored in.

CSI is a Vacuum based solution. CSI uses a very small amount fo current gen R-448A refrigerant to cool internal condenser coils, and are designed to be a completely closed (no leaks, no re-charge system. CSI’s solution may use small amounts of refrigerant, but CSI EVC is NOT a refrigeration solution for Rapi-Chill, we are an Evaporative Cooling solution.

Food service: Utilized HFCs gas leakage per year in a blast chiller and quantified the amount of that gas in each, then converted the gas leakage into CO2 equivalent

Agriculture: Assumed the agriculture chiller warehouse emitted HFC gases equivalent to blast chillers that could process the same food capacity. Then compared the HFCs savings vs utilizing EVC-300+ for the same capacity.

Variable 3: Food Waste / Shelf Life

Food service: Took the % of all food that goes to waste and applied it to the amount of lbs processed in an EVC-300. Assumed EVC-300 extends shelf life and reduces waste by 30% compared to utilizing blast chillers or other traditional methods

Agriculture: Same as food service but assumes EVC-300+’s load capacity is 600 pounds

Variable 4: Manufacturing Footprint

Food service: Assumes CO2 emissions for the construction of blast chillers and EVC-300s, and the extra emissions for building more blast chillers vs EVC-300s in order to process the same quantity per day

Agriculture: Assumes emissions per sq feet for warehouses and the savings of those

Variable 5: Food Treatment

Not modeled

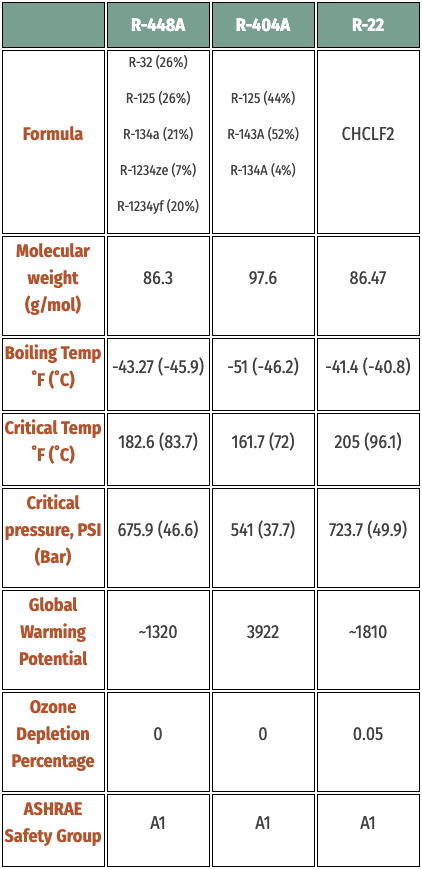

The EVC Condensing Coil Uses R-448A Freon

R-448A: Pros, Cons, & Comparisons to Other Refrigerants

Our refrigerant focus series consists of deep dives into the history, properties, suitable applications and pros and cons of some of today’s common refrigerants. This installment will focus on R-448A.

- Refrigerant Focus #1: R-32

- Refrigerant Focus #2: R-410A

- Refrigerant Focus #3: R-1234ze

- Refrigerant Focus #4: R-407A

- Refrigerant Focus #5: R-290

- Refrigerant Focus #6: R-744 (CO2)

History of R-448A as a Refrigerant

R-448A was developed between 2010 and 2015, the result of a collaborative effort among Honeywell, the University of Maryland, and Oak Ridge National Laboratory’s Building Technologies Research & Integration Center.

The stated goal of this research was to develop next-gen refrigerants, the performance of which would allow for a 50% reduction in energy consumption of the equipment in which it was used. Specifically, this work sought to synthesize a refrigerant to replace R-22, R-404A, and R-507 in low-to-medium temperature applications, such as supermarket refrigeration.

Properties of R-448A

R-448A is a low-toxicity, non-flammable blended refrigerant, classified by ASHRAE into safety group A1. It’s is a 5-part zeotropic blend, made using a combination of hydrofluorocarbon and hydrofluoroolefin constituents at the concentrations outlined below.

- R-32 (26%)

- R-125 (26%)

- R-134a (21%)

- R-1234ze (7%)

- R-1234yf (20%)

This table shows R-448A’s properties compared to the properties of the refrigerants it is intended to replace.

Pros & Cons of R-448A

R-448A: Advantages

The chief benefit of R-448A is its lessened environmental impact relative to the refrigerants it was designed to replace. It’s non-ozone depleting and has a global warming potential of 1320, which is 37% less than R-22 and 197% less than R-404.

And, while R-448A’s performance compares similarly to R-22, that refrigerant has been nearly totally phased out. And when compared to the less-regulated R-404A, R-448A resulted in a per-coil capacity increase of just over 3%. R-448A also demonstrated a significantly lower (74%) pressure drop in our hypothetical application.